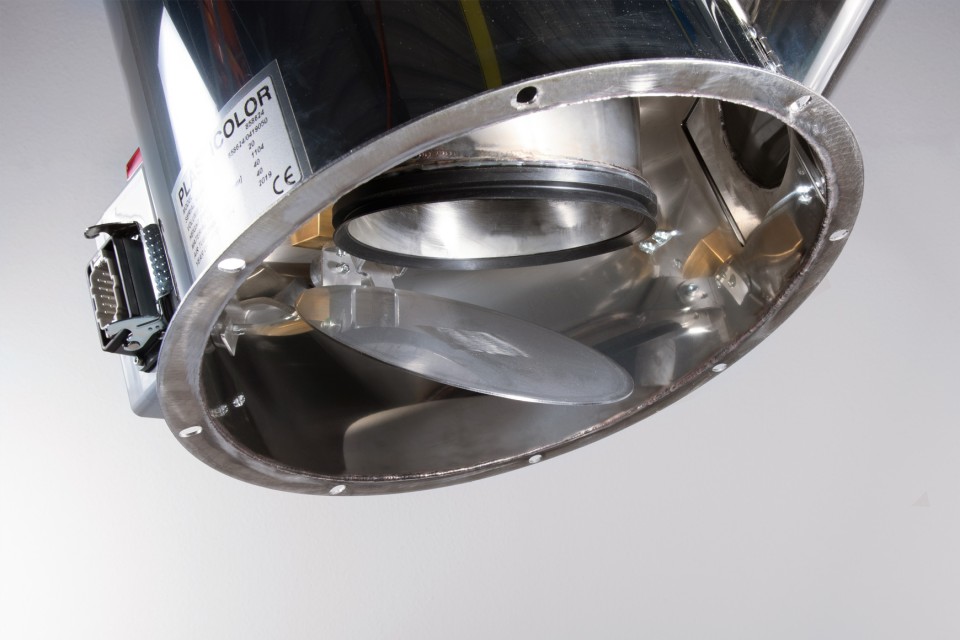

Hopper loaders

Like all components of our PLASTICOLOR system, our hopper loaders feature a modular design. They are available for different output ranges, are suitable for long conveying distances and are characterised by a robust design, simple assembly, easy handling and high operational safety. Thanks to demand-driven configuration and component selection, these devices are capable of clean, energy-efficient operation with low noise emissions.