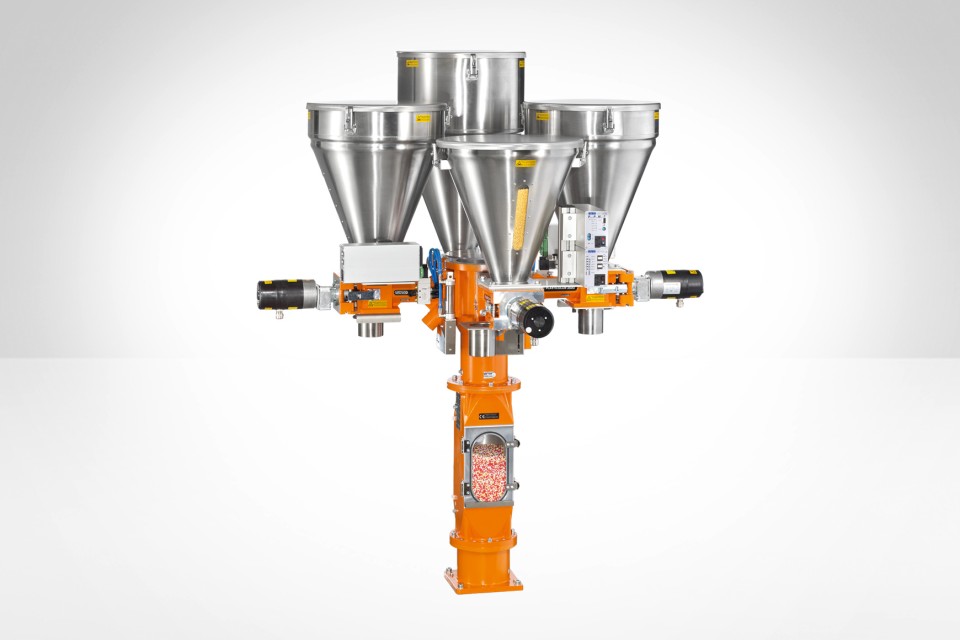

Mixing stations

In our mixing stations, all materials – including the main material – are fed via a dosing unit. A standard mixing station consists of between two and eight dosing units. Special designs with more than eight components can be easily realised thanks to the modular structure. The PLASTICOLOR system also facilitates an easy and inexpensive expansion of existing mixing stations or a conversion from volumetric to gravimetric operation.